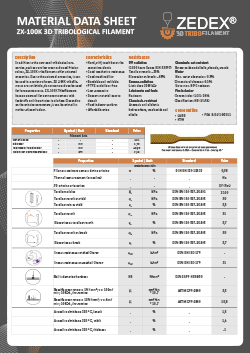

Our ZX-100K 3D-TRIBOFILAMENT is better in terms of wear and friction (*) than general 3D printing tribo-materials.

It is ideal for replacing wear parts such as bushings, spindle nuts, gears and other technical components.

(*) Test parameters: pin-on-disk test according to ASTM G99,

Surface pressure 4 MPa, sliding speed = 4m / min,

mating part’s material 100Cr6, dry running

3D TRIBOFILAMENT ZX-100K

Tensile strength

Impact resistance

Surface quality

No warping

●●●○

●●●○

●●○○

●●●●

Chemical resistance

Wear

Friction

Elasticity

●●○○

●●●○

●●●○

●●○○

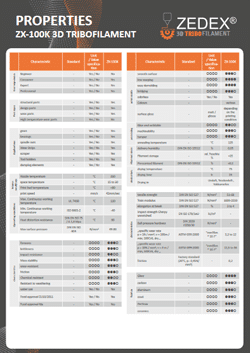

Tensile strength

Impact resistance

Surface quality

No warping

●●●○

●●●○

●●○○

●●●●

Chemical resistance

Wear

Friction

Elasticity

●●○○

●●●○

●●●○

●●○○

Tensile strength

●●●○

Impact resistance

●●●○

Surface quality

●●○○

No warping

●●●●

Chemical resistance

●●○○

Wear

●●●○

Friction

●●●○

Elasticity

●●○○

Service temperature:

± 100 °C

Annealing:

not recommended

(if printed wet)

Food compliance:

✔

(only white & blue colour)

Characteristics

- Hard, stiff, tough but at the same time elastic

- Good weathering resistance

- Good machinability

- Bondable and weldable

- PTFE and silicon free

- Low-outgassing

- Support material easy to detach

- Food industry conform

- Affordable price

Resistances

- UV radiation (1000 hours Xenon DIN 53597) Tensile strength: –25% Elongation at break: –43%

- Gamma-radiation Limit dose 1200 kGy

- Lubricants and fuels Resistant

- Chemicals, resistant Aromatic and aliphatic hydrocarbons, weak acids and alkalis

- Chemicals, not resistant Strong acids and alkalis, phenols, cresols

- Water Max. water absorption: 0.3% Dimensional changes: 0.1% Up to max. 80°C resistant

- Fire behavior Oxygen index (LOI): 24% Classification: HB (UL94)

Conformities

- FDA & EU 10/2021

- LABS

Here you'll find...

check out our company

WEBSITE

You have a question?

Than write us, we will answer u as fast as possible.